Fland VRLA Electric Tricycle Cold Storage Cargo With Songling

| Cold storage size : | |

|---|---|

| Power: | |

| SKU: | |

| Availability: | |

| Quantity: | |

| min order: 1 | |

| View wholesale prices View wholesale prices

sign in to view wholesale price | |

-

Fland

| Product name | Refrigeration Tricycle |

| Voltage | 60V 58AH 1 sets of lead-acid batteries (5 pieces/set) 72V 58AH 1 sets of lead-acid batteries (6 piecesyset) |

| Refrigerant | R404A |

| Panel thickness | -18~0℃——100mm / -25~0℃——120mm / -35~0℃——150mm |

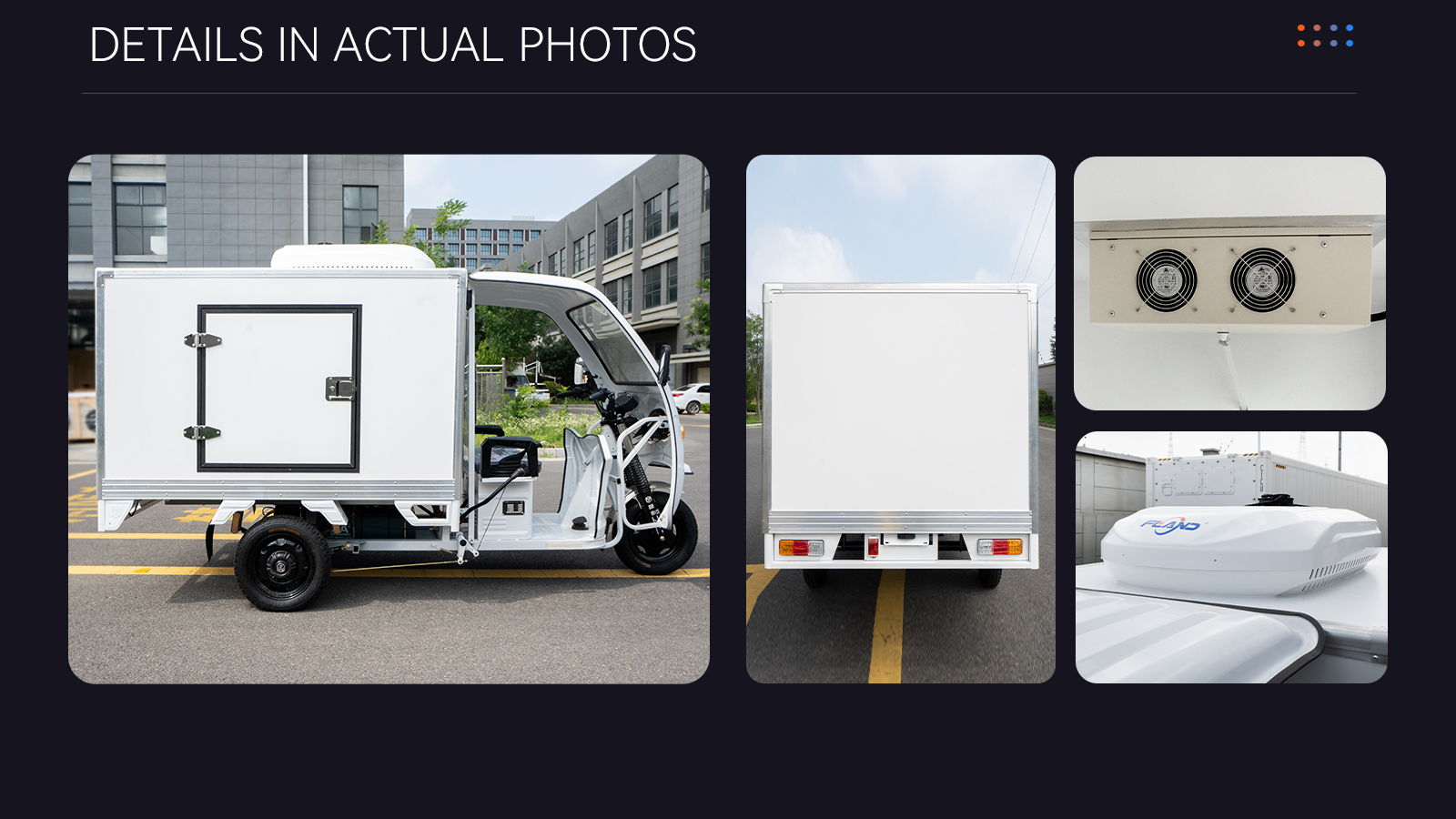

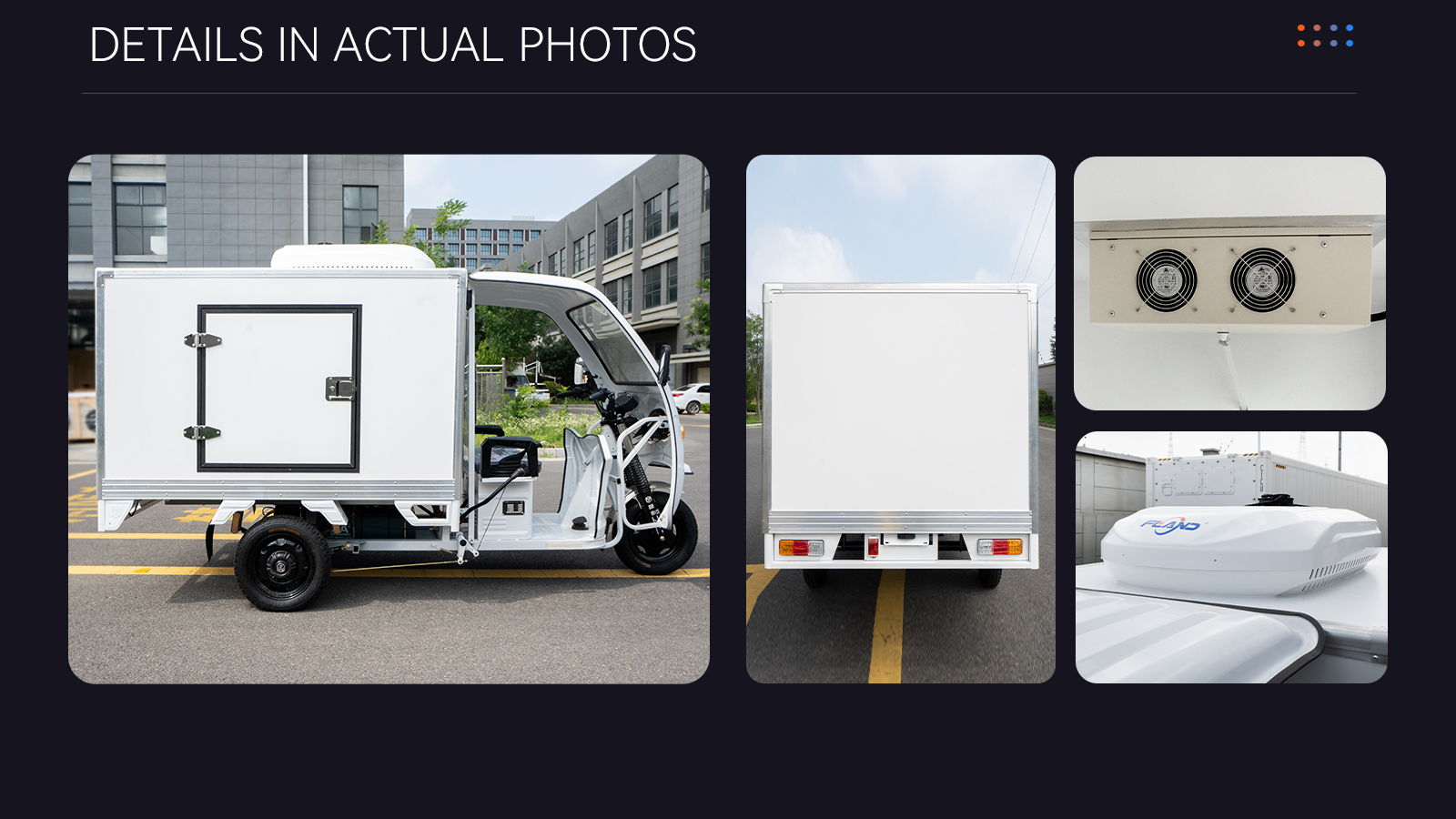

| Frame size | 3050*1030*1725mm |

| Cold storage size | 1500*1000*1000mm |

| Cold room doors | 1/customizable |

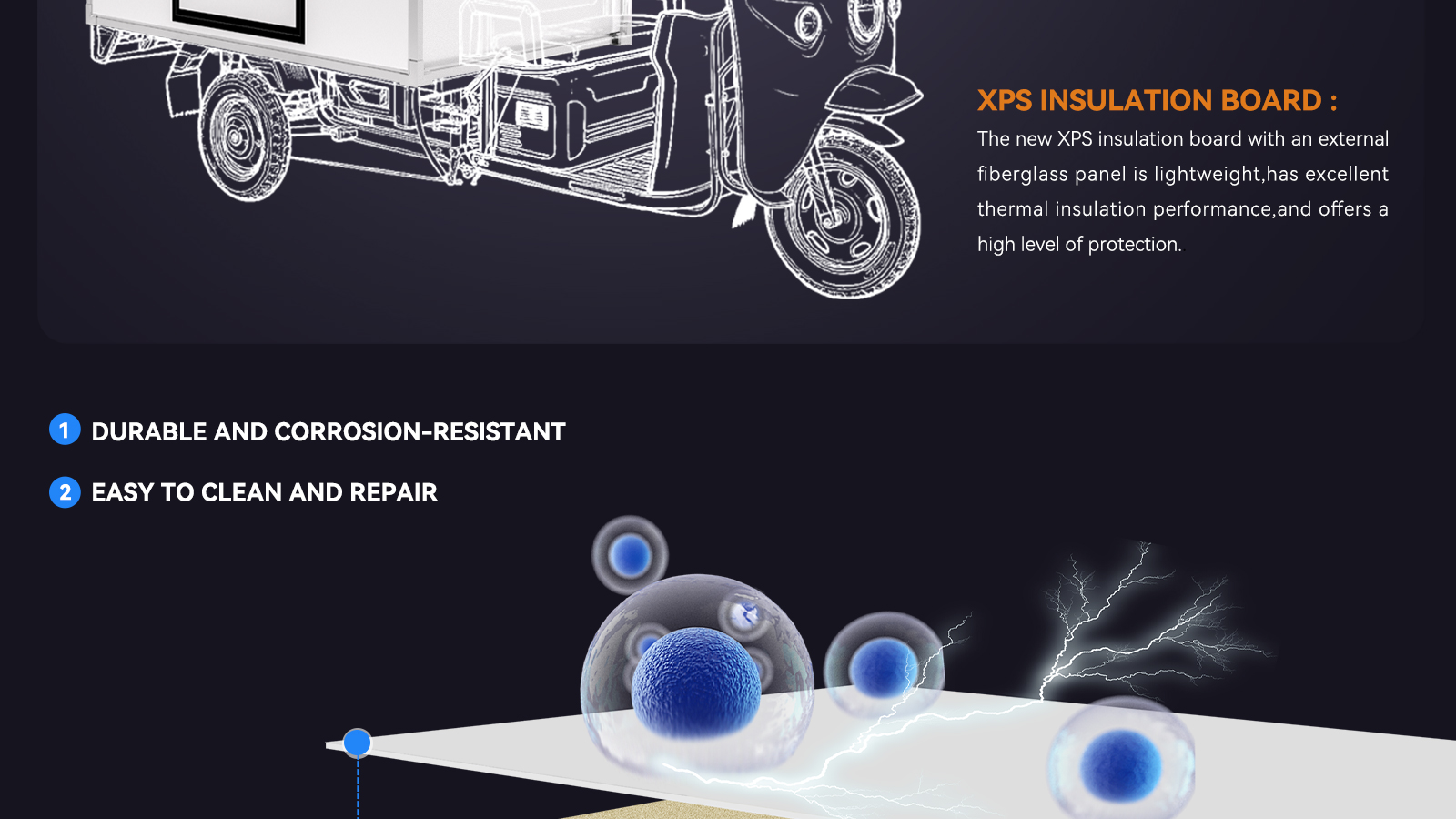

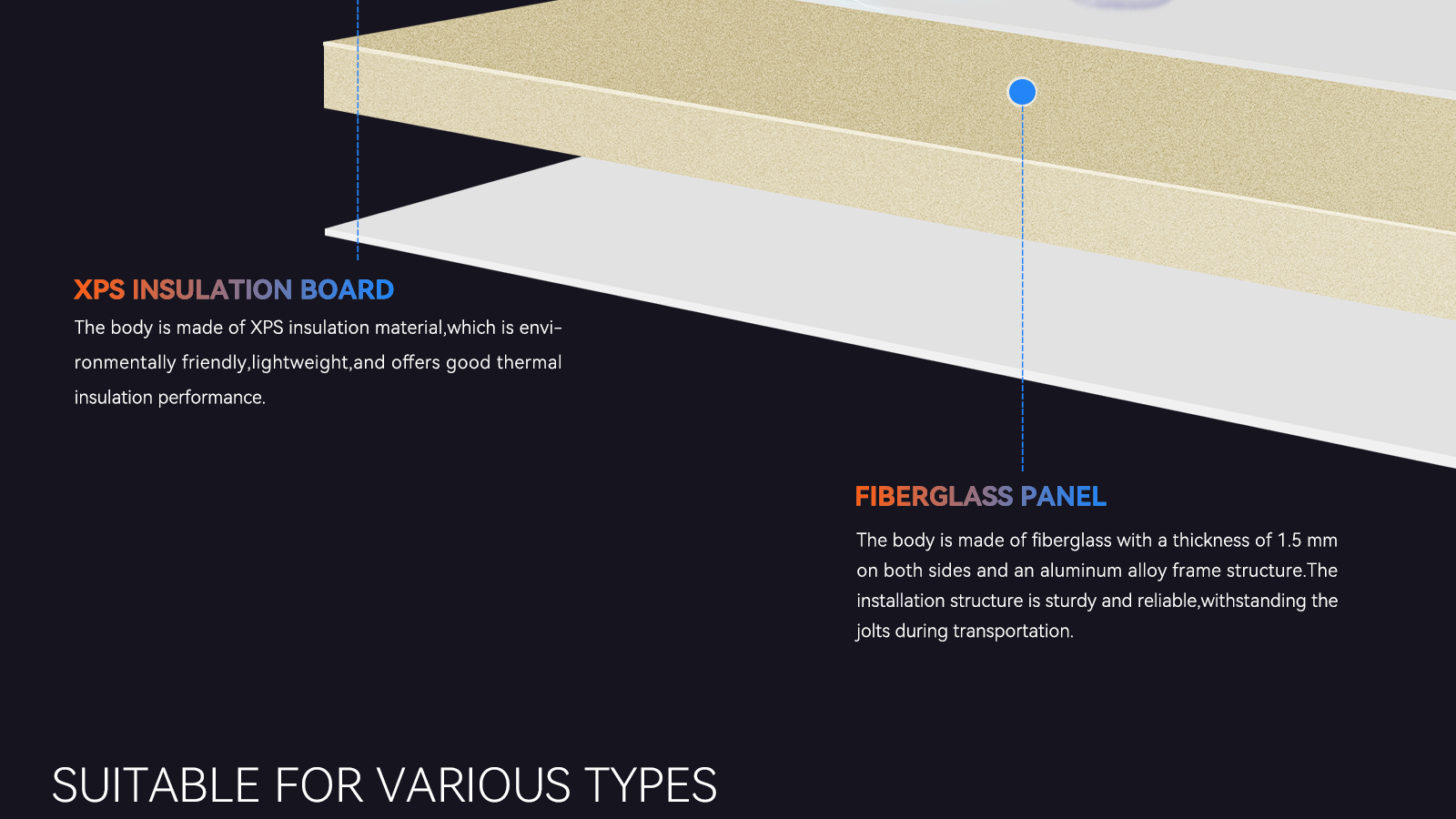

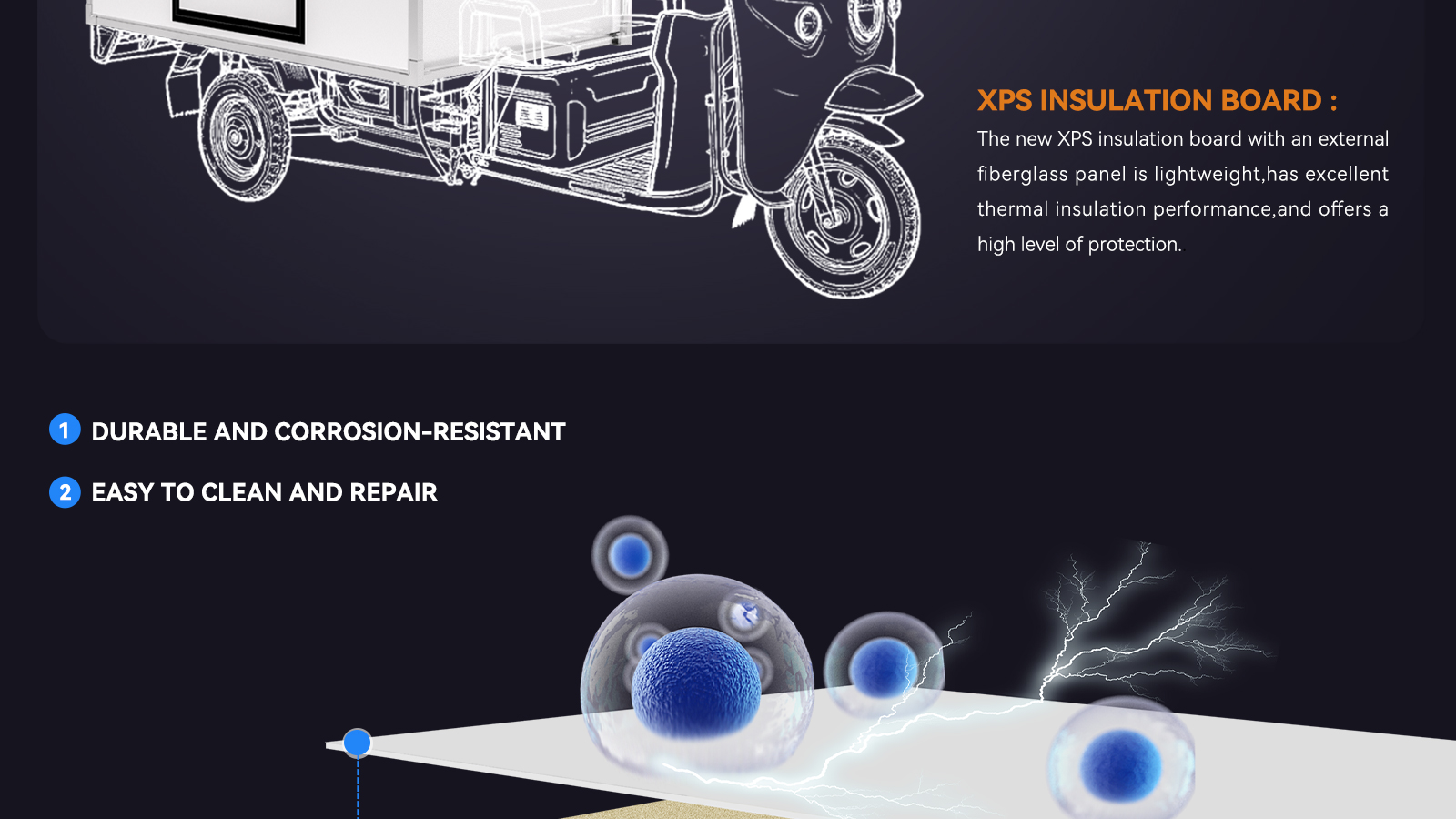

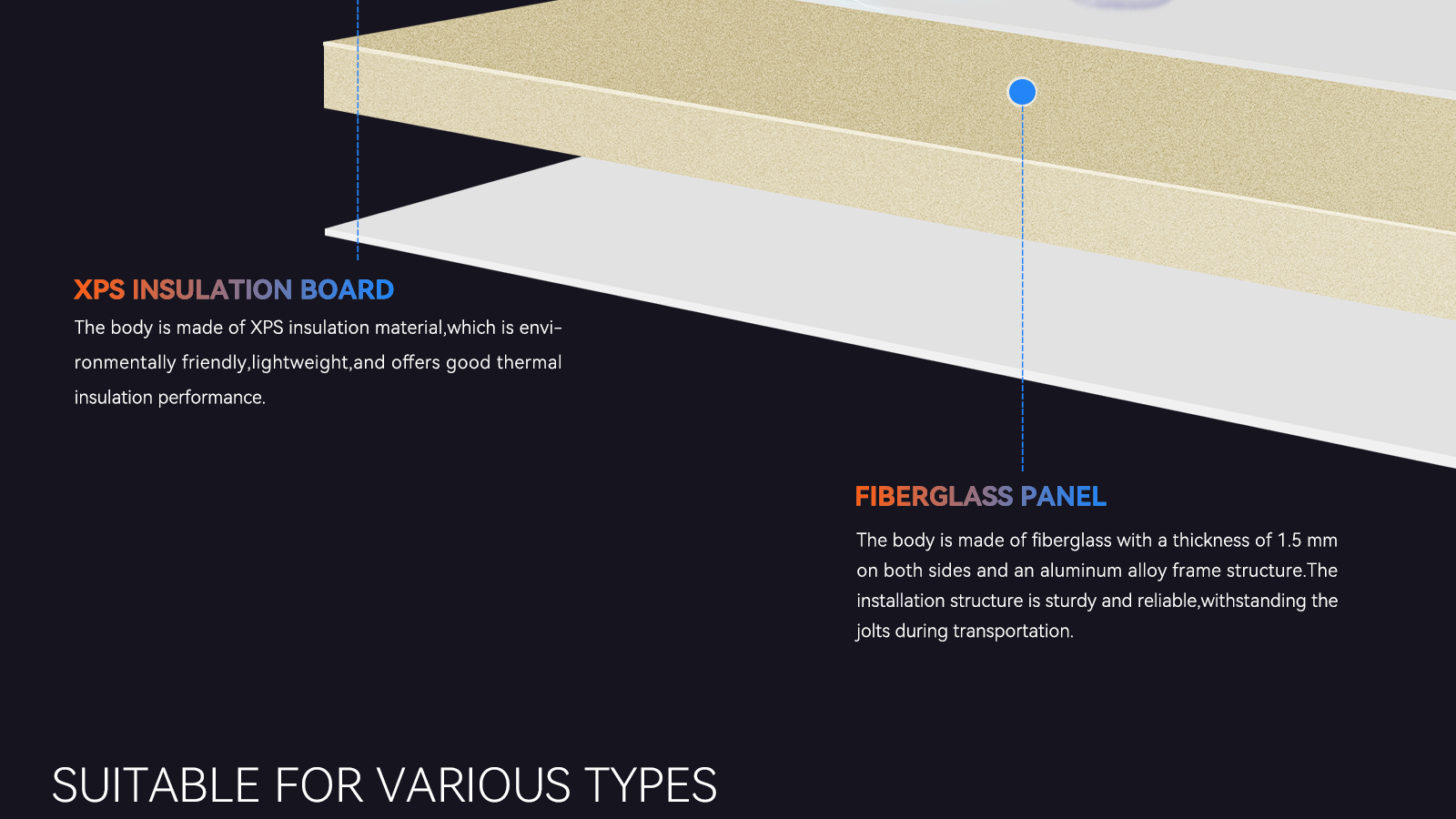

| Wall panel of cold storage room | XPS Panel |

| Cooling time | Cooling Capacity: 1920W Power: 700W |

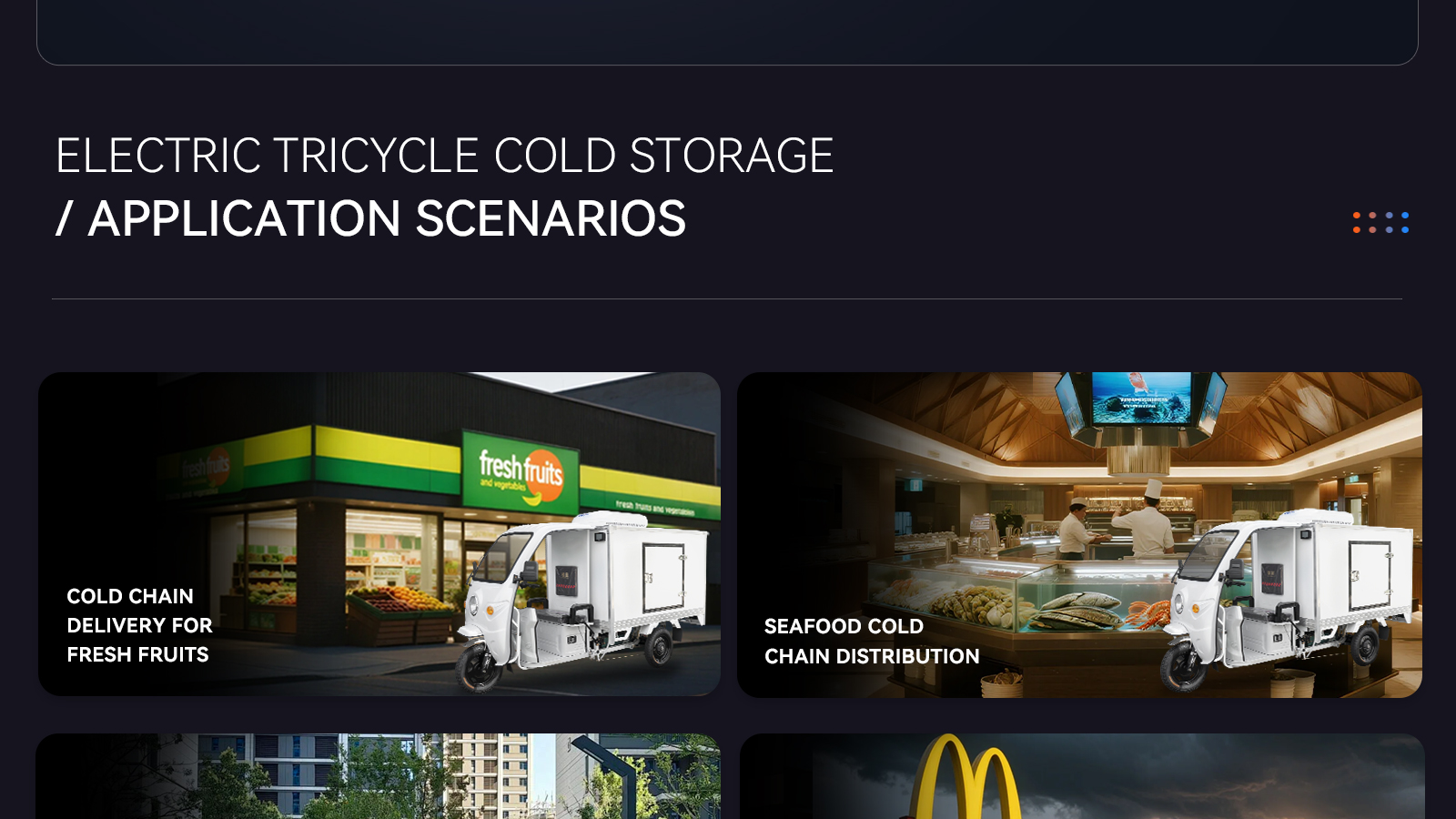

| Usage of cold room | Fruits/vegetables/meat/beer/dairy/bread/etc. |

| Certification | CE/NSF |

| Brand name | Fland |

| Place of origin | Anhui, China |

| MOQ | 1 piece |

| Warranty | 1 years |

| Product name | Refrigeration Tricycle |

| Voltage | 60V 58AH 1 sets of lead-acid batteries (5 pieces/set) 72V 58AH 1 sets of lead-acid batteries (6 piecesyset) |

| Refrigerant | R404A |

| Panel thickness | -18~0℃——100mm / -25~0℃——120mm / -35~0℃——150mm |

| Frame size | 3050*1030*1725mm |

| Cold storage size | 1500*1000*1000mm |

| Cold room doors | 1/customizable |

| Wall panel of cold storage room | XPS Panel |

| Cooling time | Cooling Capacity: 1920W Power: 700W |

| Usage of cold room | Fruits/vegetables/meat/beer/dairy/bread/etc. |

| Certification | CE/NSF |

| Brand name | Fland |

| Place of origin | Anhui, China |

| MOQ | 1 piece |

| Warranty | 1 years |

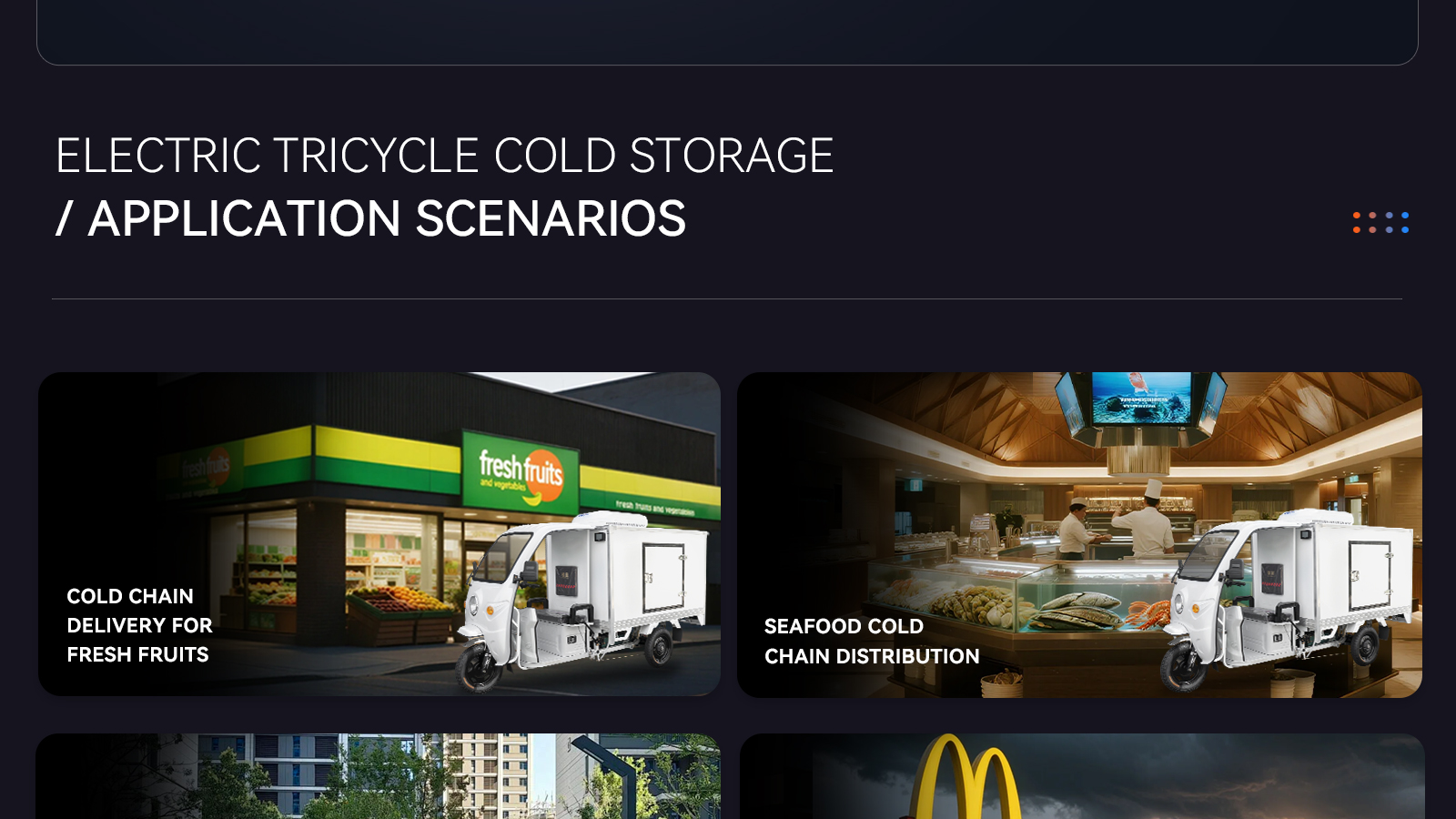

ELECTRIC TRICYCLECOLD STORAGE

Adjustable temperature: 5℃ to -18°C

HIGH EFFICIENCYREFRIGERATION

copper tube high-power compressorfast cooling with lower energyconsumpton.

SUPERLARGE AIRDIRECTION

1000L-2000L can be customizedon demand.

STRONGINSULATION

polyurethane insulation box, lock coldcapacity does not lose.

ENDURANCE

no-load range 60km lasting refrige-ration for 8 hours

SOLVING THE HIGH COST OFLAST-MILE COLD CHAIN TRANSPORT

| Fruits / Vegetables | Cold beer | Ham, bacon, dried fish | Deep-sea fish and shrimp |

OUR ADVANTAGES

| Source factory | Professional team | Worry freeafter sale | Personalizedcustomization |

EXTRA-LARGE CAPACITY E-TRIKE

High density, good seal and light weight

The flame retardant grade of polyurethane insulation material can reach B1 double-sided 0.4 color steel,Aluminum frame structure box bottom stainless steel materi.al to meet food grade requirements.

DESIGN FEATURE

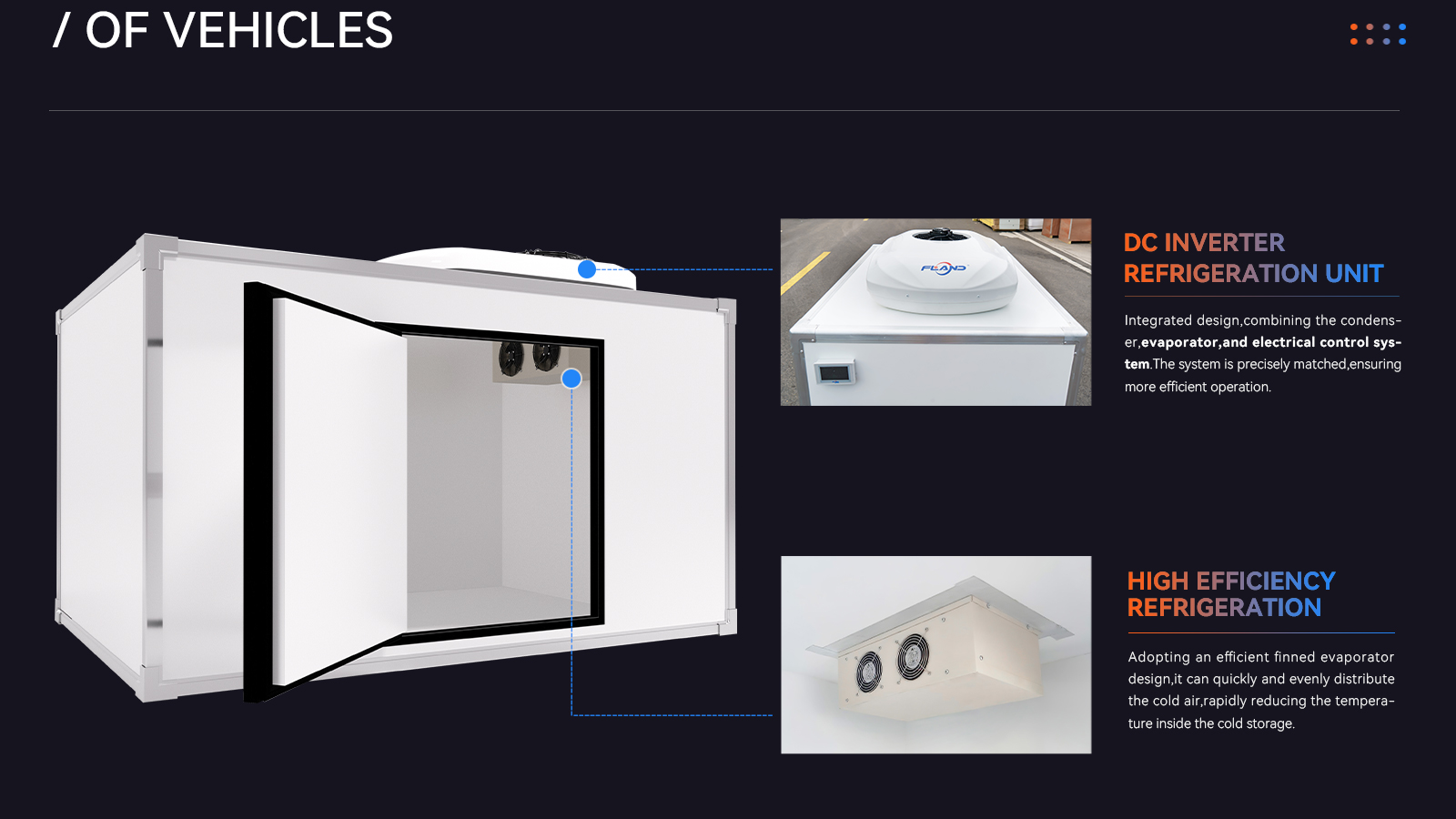

Characteristics and parameters of mobile cold source

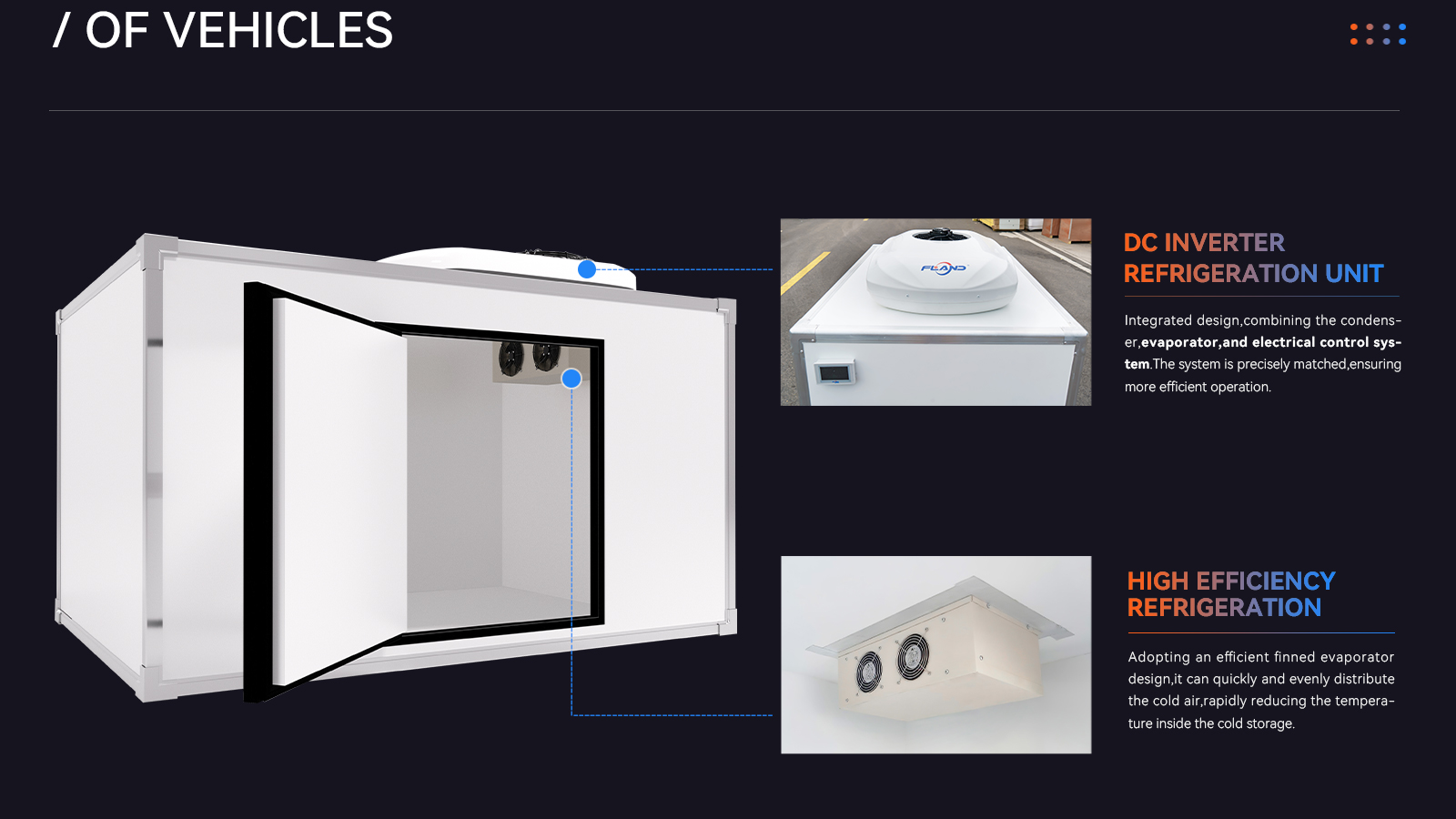

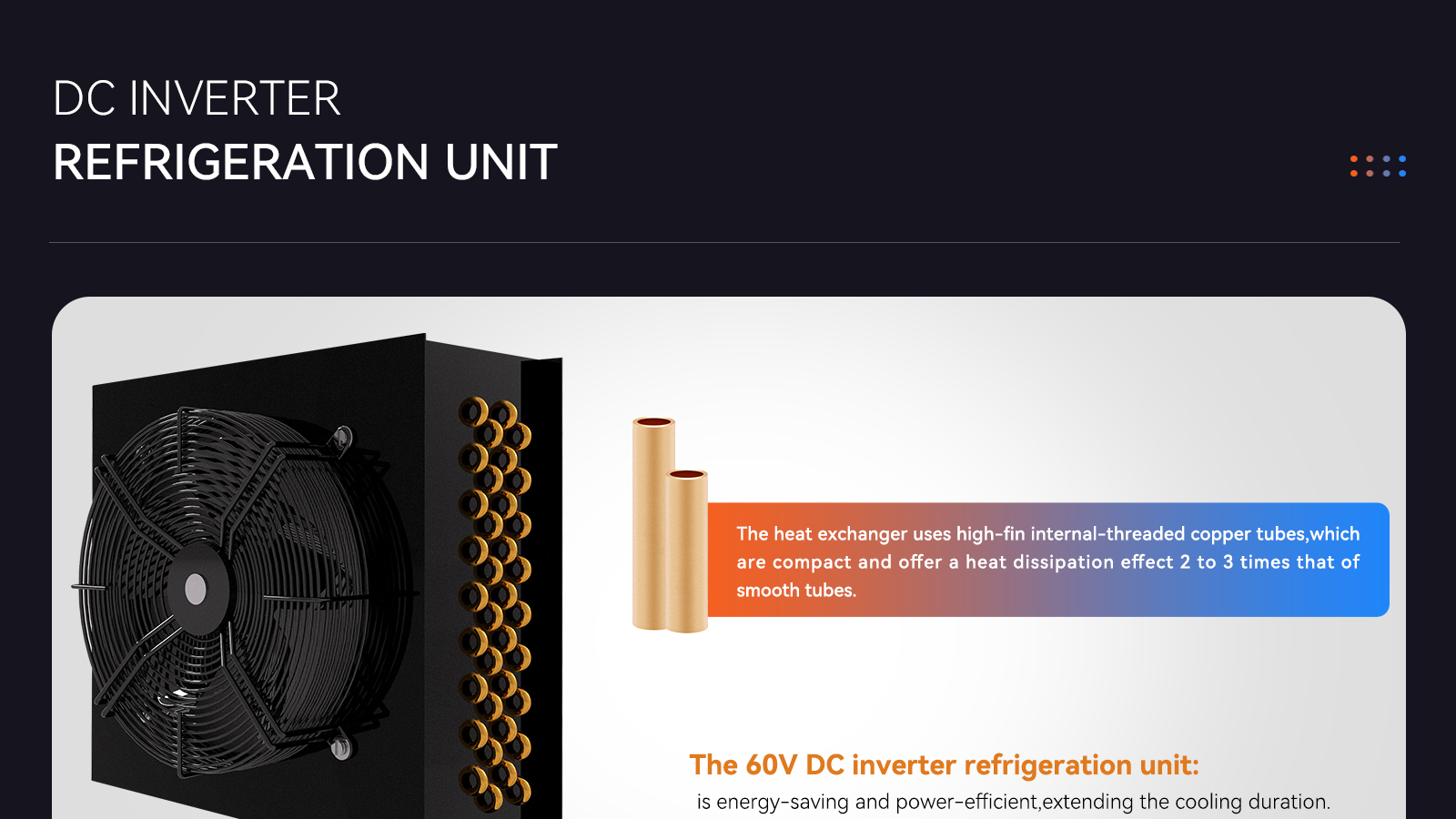

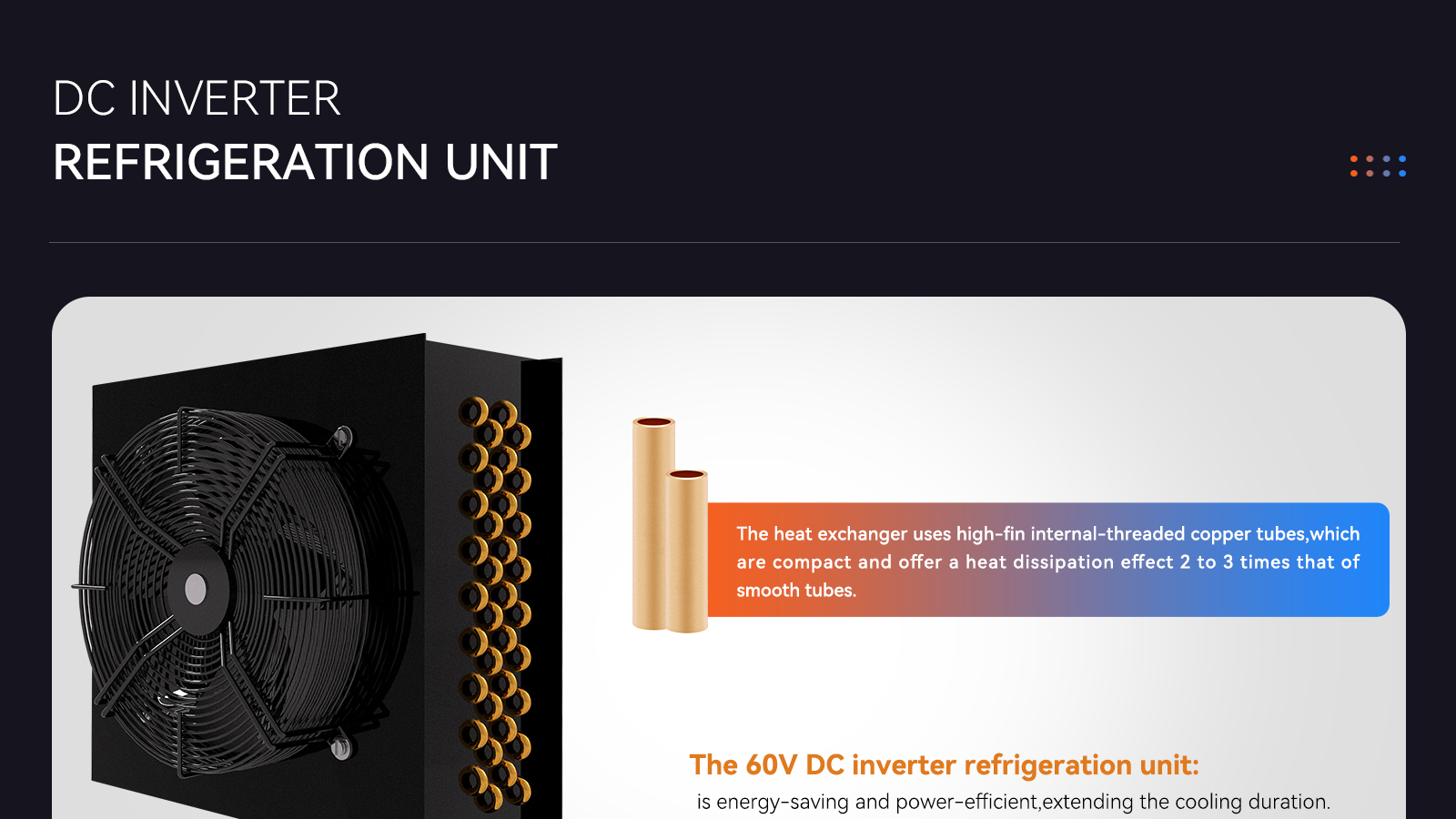

60V DC frequency conversion refrigeration unit, to meetthe needs of 1-4 cubic -20 cooling capacity

Integrated design,integrated condenser, evaporator,elec-tronic control system,system accurate matching, moreefficient operation.

The heat exchanger uses high tooth internal thread copperpipe,small size, heat dissipation effect is 2-3 times of thelight tube.

Intelligent electronic control system, automatic control,automatic defrosting,accurate temperature control.

Using R404A refrigerant, energy saving and environ-mental protection.

OPTIONAL OIL-ELECTRIC HYBRID

Add 40L fuel tank.

The range can reach about 200km.

PRODUCT DETAILS

PIR Cold Storage Panels

PU COLD STORAGE BOARD STRUCTURE

It uses the new polyurethane PIR pentane B1 foam as the hard-core material, which has excellent thermal insulation and fire resistance performance, excellent high and low temperature stability and higher fire rating. The ODP value is 0, the GWP value is extremely low, and the production process is free of freon emissions. It is green and environmentally friendly. It is the best material for building various cold storage projects. The product series includes polyurethane cold storage insulated panel, polyurethane roof insulated panel, and polyurethane hidden nail exterior wall panel.

Thermal insulation

Adopts a new generation of polyurethane pentane B1 foaming technology as a rigid core material. The dense foam is fully bonded with the surface material to form an uninterrupted heat shield, effectively blocking heat conduction and providing excellent insulation performance. Suitable for working temperatures ranging from -40℃ to+40℃.

Waterproof performance

The closed cell rate of polyurethane rigid foam insulation material can reach over95%, and the water absorption rate is ≤2%, which is better than the national standard requirements (GB/T21558-2008).97.6% of panels used for more than 20 years did not show any water seepage, and 93% of insulation performance degradation did not exceed 1%.

Fireproof and retardant

The new generation of polyurethane pentane B1 hard core material is a thermosetting material that does not melt or drip when exposed to fire or heat. it has good structural stability and meets customers' needs for higher fire resistance performance. The composite of polyurethane and metal surface materials can further improve the flame retardancy.

Hard-wearing quality

Cold storage panel is made of high-quality color coated steel or stainless-steel surface material, with high strength and excellent corrosion resistance. The cold storage panel production line adopts int'I advanced production equipment and intelligent manufacturing system to ensure stable product quality.

Healthy environment

High-quality coating on surface of cold storage panel can prevent moisture and dirt erosion,minimize the breeding of bacteria and parasites, and tightly connect the board seams for easy hygiene and cleaning, adapting to various complex situations and strict environmental requirements in the cold-chain industry

Easy installation

Cold storage panels are prefabricated and formed in the factory, with mature installation system and complete matching of various accessories, making on-site installation easier and faster, greatly shortening the construction cycle, and reducing construction labor costs and material losses.

| MAIN TECHNICAL PARAMETERS | ||

| Tenperature setting range(°C) | -18~+5℃ | |

| Applicable compartment volume(m³) | 1-4 | |

| Refrigeratingcapacity(W) | 0℃ inside the box | 3000 |

| -18°C inside the box | 1500 | |

| Refrigerating fluid | R404A | |

| Compressor(CC) | Displacement | 180 |

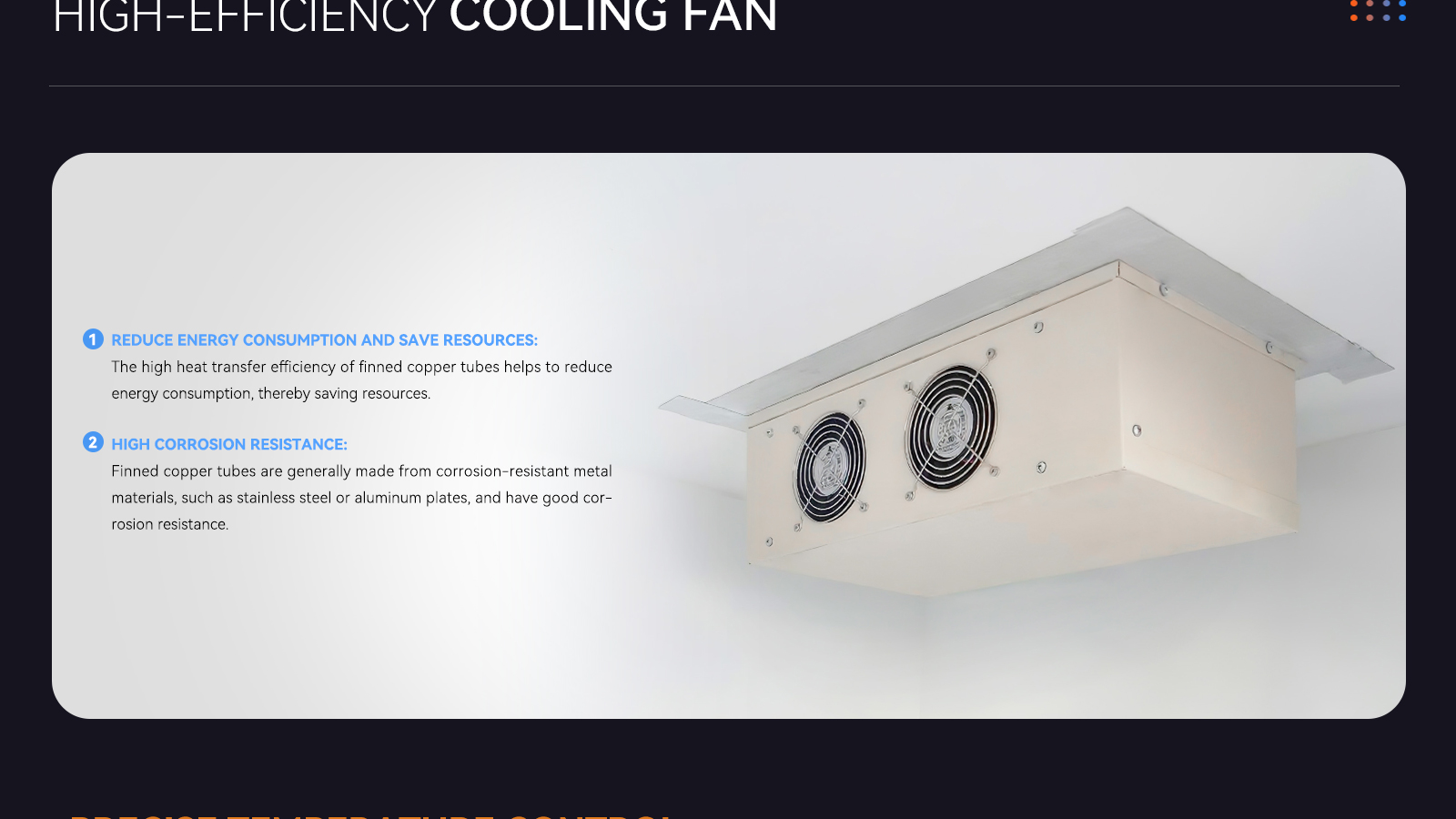

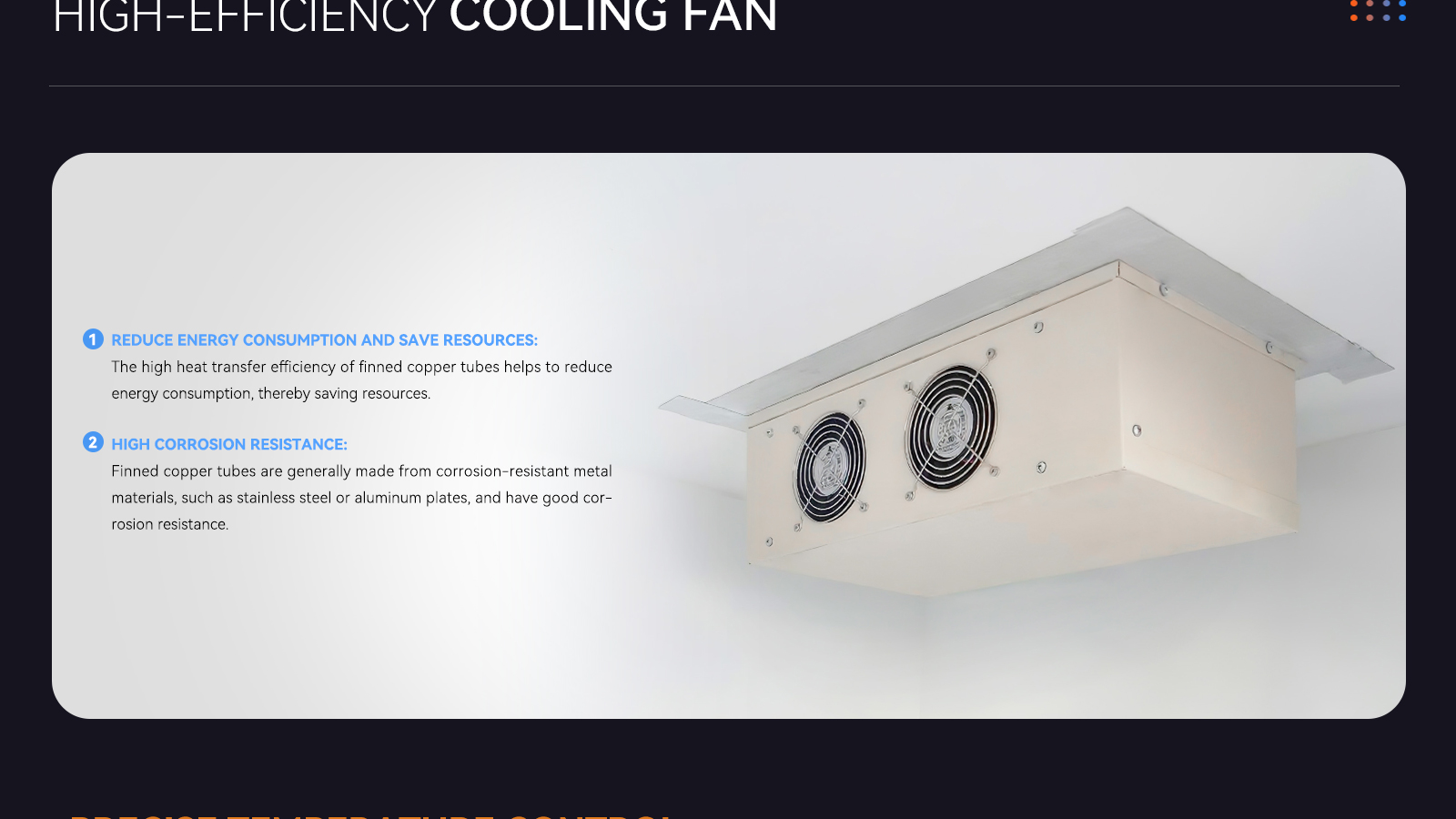

| Evaporator | Materials | Inner grooved copper tube |

| Weight(kg) | About 5kg | |

| Condenser | Materials | Inner grooved copper tube |

| Weight(kg) | About 4kg | |

| Refrigerant charge | 0.4kg | |

ELECTRIC TRICYCLECOLD STORAGE

Adjustable temperature: 5℃ to -18°C

HIGH EFFICIENCYREFRIGERATION

copper tube high-power compressorfast cooling with lower energyconsumpton.

SUPERLARGE AIRDIRECTION

1000L-2000L can be customizedon demand.

STRONGINSULATION

polyurethane insulation box, lock coldcapacity does not lose.

ENDURANCE

no-load range 60km lasting refrige-ration for 8 hours

SOLVING THE HIGH COST OFLAST-MILE COLD CHAIN TRANSPORT

| Fruits / Vegetables | Cold beer | Ham, bacon, dried fish | Deep-sea fish and shrimp |

OUR ADVANTAGES

| Source factory | Professional team | Worry freeafter sale | Personalizedcustomization |

EXTRA-LARGE CAPACITY E-TRIKE

High density, good seal and light weight

The flame retardant grade of polyurethane insulation material can reach B1 double-sided 0.4 color steel,Aluminum frame structure box bottom stainless steel materi.al to meet food grade requirements.

DESIGN FEATURE

Characteristics and parameters of mobile cold source

60V DC frequency conversion refrigeration unit, to meetthe needs of 1-4 cubic -20 cooling capacity

Integrated design,integrated condenser, evaporator,elec-tronic control system,system accurate matching, moreefficient operation.

The heat exchanger uses high tooth internal thread copperpipe,small size, heat dissipation effect is 2-3 times of thelight tube.

Intelligent electronic control system, automatic control,automatic defrosting,accurate temperature control.

Using R404A refrigerant, energy saving and environ-mental protection.

OPTIONAL OIL-ELECTRIC HYBRID

Add 40L fuel tank.

The range can reach about 200km.

PRODUCT DETAILS

PIR Cold Storage Panels

PU COLD STORAGE BOARD STRUCTURE

It uses the new polyurethane PIR pentane B1 foam as the hard-core material, which has excellent thermal insulation and fire resistance performance, excellent high and low temperature stability and higher fire rating. The ODP value is 0, the GWP value is extremely low, and the production process is free of freon emissions. It is green and environmentally friendly. It is the best material for building various cold storage projects. The product series includes polyurethane cold storage insulated panel, polyurethane roof insulated panel, and polyurethane hidden nail exterior wall panel.

Thermal insulation

Adopts a new generation of polyurethane pentane B1 foaming technology as a rigid core material. The dense foam is fully bonded with the surface material to form an uninterrupted heat shield, effectively blocking heat conduction and providing excellent insulation performance. Suitable for working temperatures ranging from -40℃ to+40℃.

Waterproof performance

The closed cell rate of polyurethane rigid foam insulation material can reach over95%, and the water absorption rate is ≤2%, which is better than the national standard requirements (GB/T21558-2008).97.6% of panels used for more than 20 years did not show any water seepage, and 93% of insulation performance degradation did not exceed 1%.

Fireproof and retardant

The new generation of polyurethane pentane B1 hard core material is a thermosetting material that does not melt or drip when exposed to fire or heat. it has good structural stability and meets customers' needs for higher fire resistance performance. The composite of polyurethane and metal surface materials can further improve the flame retardancy.

Hard-wearing quality

Cold storage panel is made of high-quality color coated steel or stainless-steel surface material, with high strength and excellent corrosion resistance. The cold storage panel production line adopts int'I advanced production equipment and intelligent manufacturing system to ensure stable product quality.

Healthy environment

High-quality coating on surface of cold storage panel can prevent moisture and dirt erosion,minimize the breeding of bacteria and parasites, and tightly connect the board seams for easy hygiene and cleaning, adapting to various complex situations and strict environmental requirements in the cold-chain industry

Easy installation

Cold storage panels are prefabricated and formed in the factory, with mature installation system and complete matching of various accessories, making on-site installation easier and faster, greatly shortening the construction cycle, and reducing construction labor costs and material losses.

| MAIN TECHNICAL PARAMETERS | ||

| Tenperature setting range(°C) | -18~+5℃ | |

| Applicable compartment volume(m³) | 1-4 | |

| Refrigeratingcapacity(W) | 0℃ inside the box | 3000 |

| -18°C inside the box | 1500 | |

| Refrigerating fluid | R404A | |

| Compressor(CC) | Displacement | 180 |

| Evaporator | Materials | Inner grooved copper tube |

| Weight(kg) | About 5kg | |

| Condenser | Materials | Inner grooved copper tube |

| Weight(kg) | About 4kg | |

| Refrigerant charge | 0.4kg | |

Customer comment

- FLAND COLD STORAGE HEART EVERY TIME

- get ready for the futuresign up for our newsletter to get updates straight to your inbox

- Navigation

- OUR PRODUCTS

- OUR PRODUCTS

- CONTACT USLandline: +86-516-8356-8099

Phone: +86-198-4431-0391

E-mail: info@flandcold.comAdd: Building 15/16/18, Standardization Phase Iii,Economic Development Zone, Baitu Town, Xiao County,Suzhou, Anhui, China - SOCIAL NETWORKS

5 / 58 Comment