How to Choose the Right Cold Storage System for Your Food Factory

Views: 0 Author: Site Editor Publish Time: 2025-11-13 Origin: Site

In the food processing industry, maintaining consistent and reliable cold storage is not just a matter of product quality—it’s a matter of safety, compliance, and profitability. Choosing the right cold storage system can directly affect your factory’s energy consumption, production efficiency, and the freshness of your products.

As a global leader in intelligent cold chain technology, Fland Refrigeration Technology Co., Ltd. has provided customized cold storage solutions for thousands of food factories worldwide. Based on our extensive experience, here’s how you can select the ideal cold storage system for your food factory.

1. Define Your Storage Needs Clearly

The first step is understanding what you are storing.

Type of products: Meat, seafood, dairy, frozen food, or ready-to-eat meals each have unique temperature and humidity requirements.

Storage capacity: Consider both your current and future needs.

Operational mode: Will the cold room be for storage, processing, or quick freezing?

Fland provides personalized design services, ensuring every project matches your temperature, humidity, and logistics workflow requirements precisely.

2. Prioritize Energy Efficiency and Reliability

Energy consumption is one of the largest costs in cold storage operations. A well-designed system can reduce power use by 20%–40%.

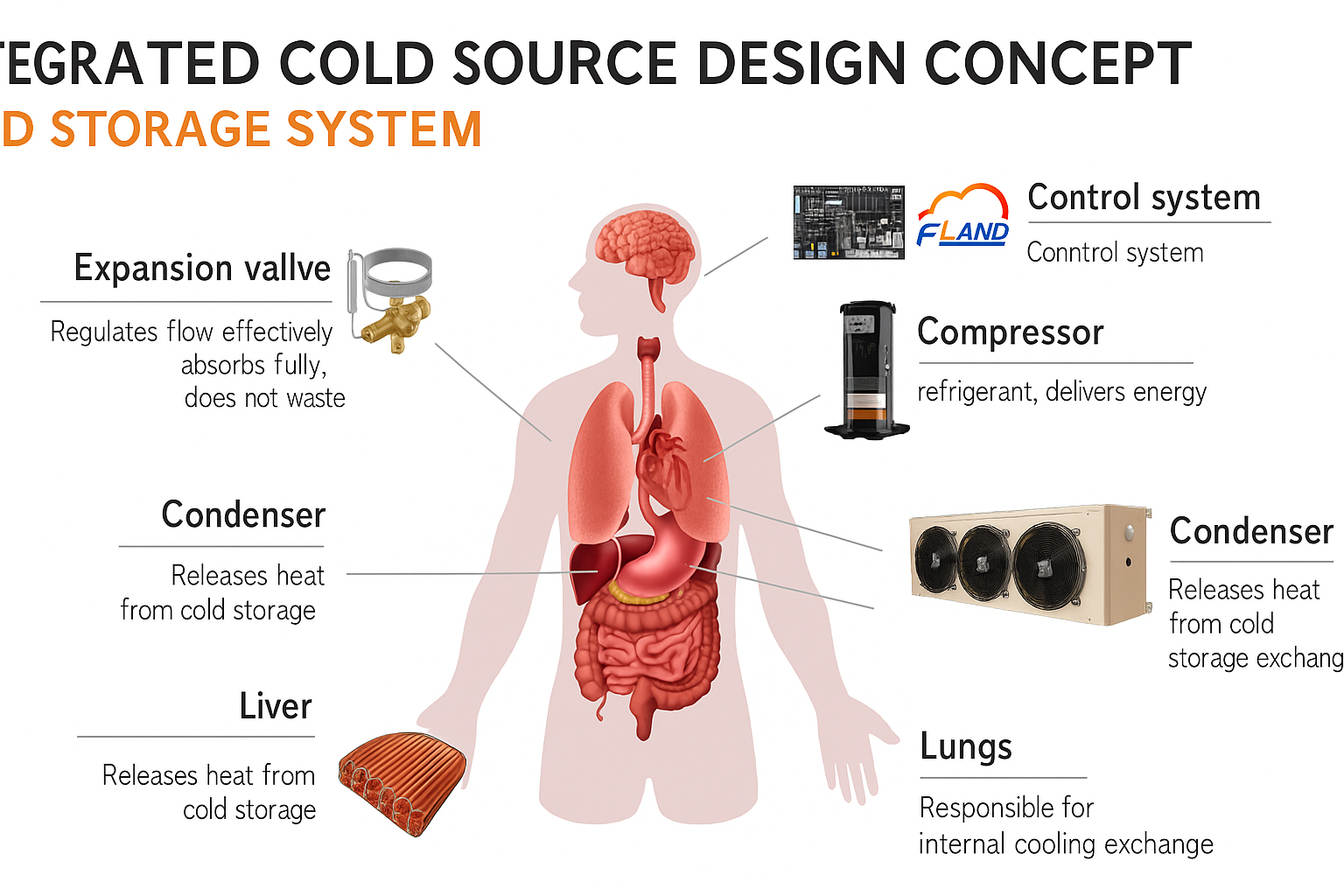

Fland’s Integrated Cold Source System combines the condenser, evaporator, compressor, and control system into one optimized unit.

Intelligent defrosting reduces energy waste by up to 80%.

ECO smart mode uses AI learning to automatically adjust operation for maximum efficiency.

Precision temperature control ensures stability and longer equipment lifespan.

This integration means your system runs efficiently and reliably, even in high-load or high-temperature environments.

3. Choose High-Quality Insulation Materials

Insulation is the foundation of cold storage performance.

Fland uses B1-grade polyurethane panels with thermal conductivity below 0.024 W/(m·K) — 50% better than ordinary panels.

They feature:

95% closed-cell foam structure, ensuring long-term insulation performance.

High fire resistance and excellent moisture protection, meeting international standards.

These panels significantly reduce heat transfer, minimize compressor load, and lower your operating costs.

4. Embrace Smart Control and Monitoring Systems

Modern cold storage systems should be intelligent and connected.

The Fland Smart Cloud Platform provides:

Real-time monitoring of temperature, voltage, current, and pressure.

Early warning and remote troubleshooting, reducing downtime.

Data analytics for energy efficiency and preventive maintenance.

By turning your cold room into a digital “cloud brain”, you gain full visibility and control over your storage environment, ensuring food safety and traceability.

5. Consider Future Scalability and Customization

Every food factory has unique space constraints and production processes.

Fland offers modular cold storage solutions that can grow with your business — from stainless steel cold rooms and containerized cold storage units, to mobile cold chain systems for flexible field operations.

We tailor each project to fit your space, workflow, and budget, ensuring long-term scalability and adaptability

6. Work with a Trusted Cold Chain Partner

Choosing a cold storage system is a strategic investment. You need a partner who understands both technology and your industry.

With over 10,000 cold storage projects built annually, and exports to 100+ countries, Fland provides:

Proven engineering expertise

24/7 after-sales service across 3,600+ support centers

Full lifecycle maintenance and AI diagnostics

Our mission is clear: Innovate technology, promote intelligent cold chains, and enhance the quality of human life.

Conclusion

Selecting the right cold storage system for your food factory means balancing technology, energy efficiency, safety, and cost. A modern, intelligent cold storage solution will not only protect your products but also boost your operational performance and sustainability.

At Fland, we build more than cold rooms — we build intelligent, integrated ecosystems for the future of food manufacturing.

- FLAND COLD STORAGE HEART EVERY TIME

- get ready for the futuresign up for our newsletter to get updates straight to your inbox

- Navigation

- OUR PRODUCTS

- OUR PRODUCTS

- CONTACT USLandline: +86-516-8356-8099

Phone: +86-198-4431-0391

E-mail: info@flandcold.comAdd: Building 15/16/18, Standardization Phase Iii,Economic Development Zone, Baitu Town, Xiao County,Suzhou, Anhui, China - SOCIAL NETWORKS